Single Scale Organic Fertilizer Packing Scales Indicator, Single scale

Product Details:

| Place of Origin: | China |

| Brand Name: | Supmeter |

| Certification: | CE |

| Model Number: | BST106-M10(AL) |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1pcs |

|---|---|

| Price: | Negotiation |

| Packaging Details: | 1pcs per box |

| Delivery Time: | 1-5days |

| Payment Terms: | L/C, T/T, Western Union |

| Supply Ability: | 10000pcs/week |

|

Detail Information |

|||

| Power Supply: | DC24V | Product Name: | TFT-Touch Ration Packing Controller |

|---|---|---|---|

| Product Size: | 226.5*163*36mm | MOQ: | 1pcs |

| Size Option: | 7 Inch And 10 Inch | Optional Communication: | Ethernet |

| Highlight: | packing controller,electrical weighing system |

||

Product Description

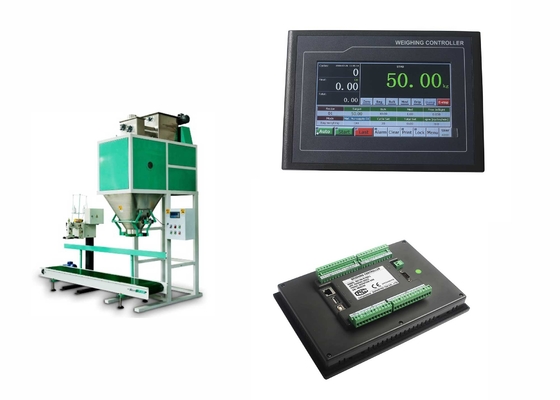

Single Hopper 10-50kg Organic Fertilizer Packing Scale Indicator, Weighing Hopper Instrument Scale for Grain Packing

Main Features:

² Suitable for Ration Packing Scale with optional Hopper-weighing Mode, Bag-weighing Mode and Loss-in-weight Mode.

² EMC design with high anti-jamming capability, suitable for industrial environment.

² Cortex-A8 CPU with 600MHz Clock, 128M RAM and 128M Flash.

² 7”/10.2” Ultralight and ultrathin TFT touch screen with embedded weighing/control module.

² Loadcell Interface

l Max. Connection Quantity: 16 Loadcells (350Ω).

l 24-bit High-precision and high-speed ∑-A/D conversion module with 1/1,000,000 internal resolution and samplingfrequency 800Hz.

l Special anti-vibration digital filtering algorithm for ensuring the weighing stability and accuracy when there is strongvibration on the load receptor, and the rapid response capability when the weight signal changes.

² I/O Interface

l 9 Definable normally open switch inputs [DI] and 18 definable normally open transistor switch outputs [DO].

l Optional ‘High/Medium/Low Speed Feed’ DOs for feeding control. Optional Low-speed Feeding Modes: Continuous Feeding Mode and Inching Feeding Mode.

l 2 Definable analog signal AOs[0~10V] for weight signal output or ‘High/Medium/Low Speed Feed’ control.

² Digital Communication Interface

l COM1[RS232]&COM2[RS485] for connecting Host IPC/PLC and LED Remote Display.

l COM[RS232] for connecting RS232 Serial Printer.

![]()

![]()

![]()

Button Operation

| Name | Operation | State Indicator | Authorization |

| 【Auto】 | Auto / Manual [Emergency Stop] switch. |

Green: Auto state. Grey: Manual state. |

All Users |

| 【Start】 | Start. |

Green: Running state. Grey: Stop state. |

|

| 【Re-run】 | Clear Alarm & Recover Running. | ||

| 【Stop】 |

Normal Stop [Last Batch]. Stop after the present batch finished. |

Flashing Red. | |

| 【E-Stop】 | Emergency Stop. | ||

| 【Alarm】 |

Alarm Query / Clear Alarm. ‘Auto/Pause’ state: Recover Running after alarms cleared. |

Red: Alarm state. | |

| 【Print】 |

Report Print:

|

||

| 【Lock】 |

Screen-locking: Locking/unlocking the operating buttons of main user interface. Auto Screen-locking: Refer to parameter [901]. |

Flashing Red: Locked. Grey: Unlocked. |

|

| 【Menu】 | Enter Main Menu. | ||

| 【User】 | User Login. Display: Operator / Engineer / Admin. | ||

| 【Zero】 | Manual Zero [No Power-down Protection]. | Flashing green. | |

| 【Bag】 | Bag-clamp/release Request. |

Green: Bag-clamping state. Grey: Bag-releasing state. |

|

| 【Bulk】 | Manual Start/Stop Bulk Feed. | Green: Working state. | |

| 【Med】 | Manual Start/Stop Medium Feed. | ||

| 【Drip】 | Manual Start/Stop Dribble Feed. | ||

| 【Dump】 | Manual Start/Stop Dumping. | ||

| 【Mat.】 | Manual Start/Stop Supplying Materials into Feeding Bin. | Flashing green. | |

| 【Clear】 | Clear Screen: Clear the display values of Feeding Weight, Totalized Weight, Batch Count and Cycle Speed. |

Engineer Administrator |

Error Messages

| Message | Alarm Cause | Solution |

| RAM Fault | The chip RAM is damaged. | Replace the chip RAM. |

| EEPROM Fault | The chip EEPROM is damaged. | Replace the chip EEPROM. |

| Parameter Error | The chip EEPROM is damaged. | Replace the chip EEPROM. |

| Weighing Signal Error | Weighing signal reversed or not connected. | Connect the loadcell correctly. |

| ADC Fault | The chip ADC is damaged. | Replace the ADC module. |

| Over ADC Range | Weighing signal exceeds A/D conversion range. |

1. Check if the loadcell is connected. 2. Check if the capacity of loadcell is too small. 3. Check if the loading weight is too big. |

| Overload Alarm | Weight > (Scale Capacity + 9 × Scale Division). |

1. Check if the set value of parameter [102] ‘Scale Capacity’ is reasonable. 2. Check if the loadcell is connected. 3. Check if the capacity of loadcell is too small. 4. Check if the loading weight is too big. |

| Internal Data-bus Fault | Please contact manufacturer. |

Main User Interfaces