Hydraulic Scales System Shovel Loader Indicator For 1-12ton Bucket Wheel Loaders

Product Details:

| Place of Origin: | China |

| Brand Name: | Supmeter |

| Certification: | CE |

| Model Number: | BST106-N59[B] |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1pcs |

|---|---|

| Price: | Negotiation |

| Packaging Details: | 1set/carton |

| Delivery Time: | 3-30 working days |

| Payment Terms: | T/T, Western Union |

| Supply Ability: | 200pcs/month |

|

Detail Information |

|||

| Power Supply: | DC24V±20% | Accuracy Grade: | III |

|---|---|---|---|

| Verification Accuracy Of Weighing Indicator: | 0.02% | Accuracy Of Single-Bucket-Weight: | 0.5%~1.0% |

| Accuracy Of Totalized Loading Weight: | 1.0% | IP Grade: | IP65 |

| Highlight: | Hydraulic Scales Shovel Loader Indicator,Shovel Loader Indicator,Shovel Loader Indicator CE |

||

Product Description

Hydraulic Scales System For 1-12ton Bucket Wheel Loaders

System Configuration

- 1 Weighing Indicator with Thermal Printer.

- 1 Position Sensor.

- 2 Oil Pressure Sensors.

- 2 Plate Type Three-way Joints.

- 1 Mounting Fitting.

Technical Specifications:

| Display | 640×480 TFT color display screen for English character display | |

| Weight Display Range | -99,999~+999,999 | |

| System Weighing Range | 100~12,000kg | |

| Scale Division | Optional 1, 2, 5, 10, 20, 50kg | |

| Display Resolution | 1/100,000 | |

| Position Sensor Input Interface | 2 Switch signal Input | |

| Output Voltage | DC12V | |

| Max. Output Current | 100mA | |

| Oil Pressure Sensor Interface | 2 Switch signal Input | |

| Excitation Voltage/Max.Current | DC12V/100mA & DC5V/100mA | |

| Signal Input Range | Optional 0~20mV, 0~5V[Factory Set Value] | |

| ∑-△ADC | 24-bit, 1,000,000 internal code used | |

| Sampling Frequency | 400Hz | |

| Non-linearity | 0.005%FS | |

| Digital Communication Interface | COM1 | RS232 |

| Report Print | 10000 Loading Records can be saved, queried and printed, and each record can contain 50pcs Single-bucket-loading-weight value | |

| IP Grade | IP65 | |

Installation of Position Sensor

Position sensor includes two modules:

- Proximity Switch Module: Main Mounting Plate with a chute for length adjustment, Sub-mounting Plate with a chute for angle adjustment, Upper Proximity Switch and Lower Proximity Switch [Detecting Distance: 1~8mm].

- Magnet Module: Thread Pole, Weld-nut, Tight-nut, Nylon Block, Magnet Block.

![]()

1: Lift-arm Seat; 2: Lift-arm; 3: Main Mounting Plate; 4: Sub-mounting Plate; 5: Weld-nut;

6: Thread Pole; 7: Nylon Block; 8: Fastening Nut for Position Ajustment; 9: Magnet Block; 10: Upper Proximity Switch; 11: Upper Proximity Switch; 12: Fastening Nut for Length Ajustment; 13: Fastening Nut for Angle Ajustment.

Sensing Distance Adjustment: Adjust the sensing distance between the Magnet Block and the Proximity Switch to 3~5mm.

Suggestion: Install the position sensor on the lift-arm seat and lift-arm which are at the same side that the weighing indicator installed on.

![]()

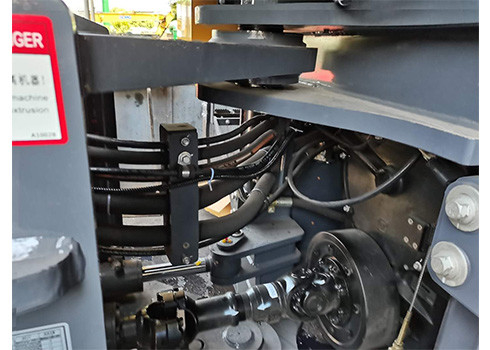

Installation of Oil Pressure Sensor

![]()

Application

![]()