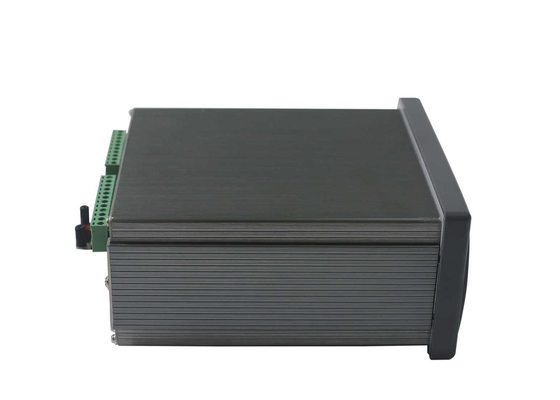

Digital Weighing Instrument Belt Scale Controller With Profibus - DP / Ethernet

Product Details:

| Place of Origin: | China |

| Brand Name: | Supmeter |

| Certification: | CE |

| Model Number: | BST100-E01 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1pcs |

|---|---|

| Price: | Negotiation |

| Packaging Details: | 1pcs/box |

| Delivery Time: | 3-10 working days |

| Supply Ability: | 500pcs per month |

|

Detail Information |

|||

| Power Supply: | AC220V | Open Swith Input: | 3DI |

|---|---|---|---|

| Open Repay Output: | 4DO | Accuracy Of Flow Control: | 0.5%~1.0% |

| COM1: | Optional RS232/RS485 | Max Connect: | 8loadcells |

| Protection Level Of Front Panel: | IP65 | COM2: | RS232 |

| Highlight: | belt weigher indicator,digital indicator with remote display |

||

Product Description

Belt Scale Digital Weighing Instrument Controller With Profibus-DP/Ethernet

Main Features:

- Suitable for Ration Belt Weighfeeder with Ration Flow Feeding & Ration Weight Batch Control.

- EMC design with high anti-jamming capability, suitable for industrial environment.

- 32-bit ARM CPU with 72MHz clock & high arithmetic speed.

- 128×64 LCD display screen with 7 background colors for English display.

- 16-key English keypad.

- Menu&Shortcut mode operation with key tone.

- 24-bit High-precision and high-speed ∑-△A/D conversion module with 1/1,000,000 internal resolution and sampling frequency 400Hz.

- Broad-range speed pulse input circuit.

- Special anti-vibration digital filtering algorithm for ensuring the weighing stability and accuracy when there is strong vibration on the load receptor, and the rapid response capability when the weight signal changes.

- Max. Connection Quantity: 8 Loadcells (350Ω).

- Auto-locking, Key-locking, Key-unlocking, Digital Setting&Calibration and I/O Testing functions available.

- Auto Zero Tracking, Speed Calibration and Belt Length Calibration functions available.

- One optional ‘Flow Setpoint’ analog signal input [AI: 4~20mA].

- Max.3 definable ‘Flow/Control Current /…’ analog signal outputs [AO: 4~20mA].

- Quick and steady PID ration feeding control.

- 3 Definable normally open switch inputs [DI] and 4 definable normally open relay switch outputs [DO].

- The feeder and belt weigher can be started and stopped by DI&DO signal.

- 1 ‘Totalized Weight High-speed Pulse’ output [PO].

- 2 Optional communication ports for connecting IPC/PLC, LED Remote Display, Serial Printer and Wireless Module.

- Weight Records per shift/day/month of a year can be queried and printed.

- With the multitasking mode, the weighing&control process will not be interrupted by parameter setting and the other operations.

Model Vertical Panel-mounting Operation Interface

![]()

Keypad Operation

If there is not any keypad operation in one minute and it’s not in the processes of ‘F2 Calibration’ & ‘F6 Factory Adj.’, the controller will return to ‘Main Display Interface’ automatically.

| Menu Operation | |

| Key Name | Description |

|

【MENU】 |

Enter Main Menu. Exit. |

| 【ENT】 | Enter/Save. |

| 【▲】 |

Cursor shifts up or left. Display the previous interface or option. |

| 【▼】 |

Cursor shifts down or right. Display the next interface or option. |

| 【0~9】 | Digit Input. |

| Quick Operation | |

| 【LOCK】 |

|

| 【F1】 | Return to the initial display interface. |

| 【SET】 | Flow Set Value Setting. |

| 【ADJ-】 | Control Current -1mA. |

| 【ADJ+】 | Control Current +1mA. |

| 【AUTO】 | ‘Manual/Auto’ Control Mode Selection. |

| 【EXT】 | ‘Internal/External’ Flow Set Mode Selection. |

| 【ZERO】 | Zero Calibration. |

| 【CAL】 | Dynamic Span Calibration. |

| 【CLS】 | Clear Screen: Clear display value of Totalized Weight. |

| 【REC】 | Query and print Weight Record. |

| 【PRINT】 | Print. |

State Indication

| LED Lamp | Description |

| [RUN] |

ON: Weighing state. |

| [AUTO] |

Feeding control mode: |

| [EXT] |

Flow Set Mode: |

| [ALARM] | Alarm. |

| [LOCK] |

ON: Key-locked. |

Ration Flow Auto-Feeding System

![]()