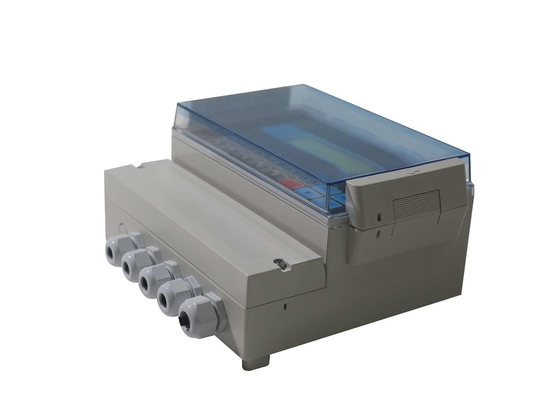

Waterproof LCD Weigh Feeder Controller IP65 Protection Level 235.5*227.5*119.5mm

Product Details:

| Place of Origin: | China |

| Brand Name: | Supmeter |

| Certification: | CE |

| Model Number: | BST100-D52 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1pcs |

|---|---|

| Price: | negotiation |

| Packaging Details: | 1pcs/box |

| Delivery Time: | 3-10 working days |

| Payment Terms: | T/T, Western Union |

| Supply Ability: | 1000pcs/month |

|

Detail Information |

|||

| Power Supply: | AC220V | Outline Size: | 235.5*227.5*119.5mm |

|---|---|---|---|

| Protection Level: | IP65 | Accuracy Grade: | 0.5 |

| Highlight: | weighing scale indicator,digital indicator with remote display |

||

Product Description

Corrosion-proof LCD Belt Weigher Indicator With Weight Totalizing For Corrosive Gas Environment

Main Features:

- Suitable for belt weigher.

- EMC design with high anti-jamming capability, suitable for industrial environment.

- 32-bit ARM CPU with 72MHz & higher arithmetic speed.

- 160×32 dots LCD display screen with yellow-green background for English display.

- Menu&Shortcut mode operation with key tone.

- High-precision ∑-△A/D conversion technology and broad-range speed pulse input circuit.

- Max. Connection Quantity: 8 Loadcells (350Ω).

- Auto-locking, Key-locking, Key-unlocking and Digital Setting&Calibration functions available.

- Auto Zero Tracking, Speed Calibration and Belt Length Calibration functions available.

- Optional AO [4~20mA] module for Flow signal output (COM1 port will be occupied).

- 2 Optional communication ports for connecting IPC/PLC, LED Remote Display, Serial Printer and Wireless Module.

- Corrosion-proof, water-proof, dust-proof and shock-proof shell for model wall-mounting.

- Weight Records per shift/day/month of a year can be queried and printed.

- With the multitasking mode, the weighing process will not be interrupted by parameter setting and the other operations.

Safety Precaution

- Lithium Battery Installation

A Lithium battery should be equipped in the product. If it is not allowed to be transported together with the product because of embargo, please make a purchase according to the model offered by us and install it by yourself.

- Application environment

Make sure that this product works under the environment where is accord with the technical specifications.

Do not open the shell before power-off.

- Controller Protection

For avoiding bodily injury from electric shock accident and separating the controller from strong interference, the metal shell of the controller should be grounded directly with the ground resistance being less than 4Ω.

- Scale Frame Protection

For avoiding bodily injury from electric shock accident and separating the loadcells from strong interference, the scale frame should be grounded directly with the ground resistance being less than 4Ω.

- Cable Laying

Weighing signal, speed signal, analog signal and communication signal cables should be laid in pipes, and do not lay them together with power cables.

- Power Supply

The power supply of the controller should be separated from the power supply of the driving devices.

Please make sure that the inputted voltage is correct before power-on.

If the voltage fluctuation exceeds the allowed range, please use a power stabilizer to get a stable voltage supply.

- Environmental Protection

Before the Lithium battery equipped in the product being discarded, please insulate its positive or negative pole, do not put it into fire.

While being discarded as worthless, the product should be processed lawfully as leady industrial waste for environment protection.

- Other Notes

The installation, wiring and maintenance should be operated by the engineers with the relevant professional knowledge and safety operation ability.

Although being not described in this manual, the relevant safety operating procedures and standards should be followed.

Technical Specification:

| Display | 160*32 LCD display screen with yellow-green background |

| Force Value Display Range | -60,000~+60,000 |

| Force Capacity | Setting Range 1~60,000 |

| Power Supply | AC220V |

| Loadcell Excitation Voltage/Current | DC10V/250mA |

| Max. Loacell Connectable No. | 8 loadcells (350Ω) |

| Signal Input Range | 0~25mV |

| Sampling Frequency | 400Hz |

| Speed Signal Input Range | 0.5-3000Hz |

| COM1 | Optional RS232/RS485/RS422/Profibus-DP/Ethernet |

| COM2 | RS232 |

| Outline Size(W*H*D) | 235.5*227.5*119.5mm |

| Accuracy Grade | 0.5 |

| IP Grade | IP65 |

Operation Interface

Model Panel-mounting / Wall-mounting Operation Interface

![]()

Model Panel-mounting / Wall-mounting Keypad Operation

| Key Name | Description |

| 【MENU】 | Enter Main Menu / Exit. |

| 【ENT】 |

Enter/Save. Return to the initial display interface. |

| 【▲】 |

Cursor shifts up or left. Display the previous interface or option. |

| 【▼】 |

Cursor shifts down or right. Display the next interface or option. |

| 【0~9】 | Digit Input. |

| Quick Operation | |

| 【LOCK】 |

Key-locking. Key-unlocking. |

| 【F1】 | Static Span Calibration with Hanging Weight. |

| 【ZERO】 | Zero Calibration. |

| 【CAL1】 | Dynamic Span Calibration. |

| 【CAL2】 | Static Span Calibration with Chain Weight. |

| 【SEG】 | Segmenting Span Correction. |

| 【SPD】 | Speed Calibration. |

| 【LEN】 | Belt Length Calibration. |

| 【TIME】 | Date/Time Setting. |

| 【CLS】 | Clear Screen. |

| 【REC】 | Query and Print Weight Record. |

| 【PRINT】 | Print. |

Model Wall-mounting Installation

![]()